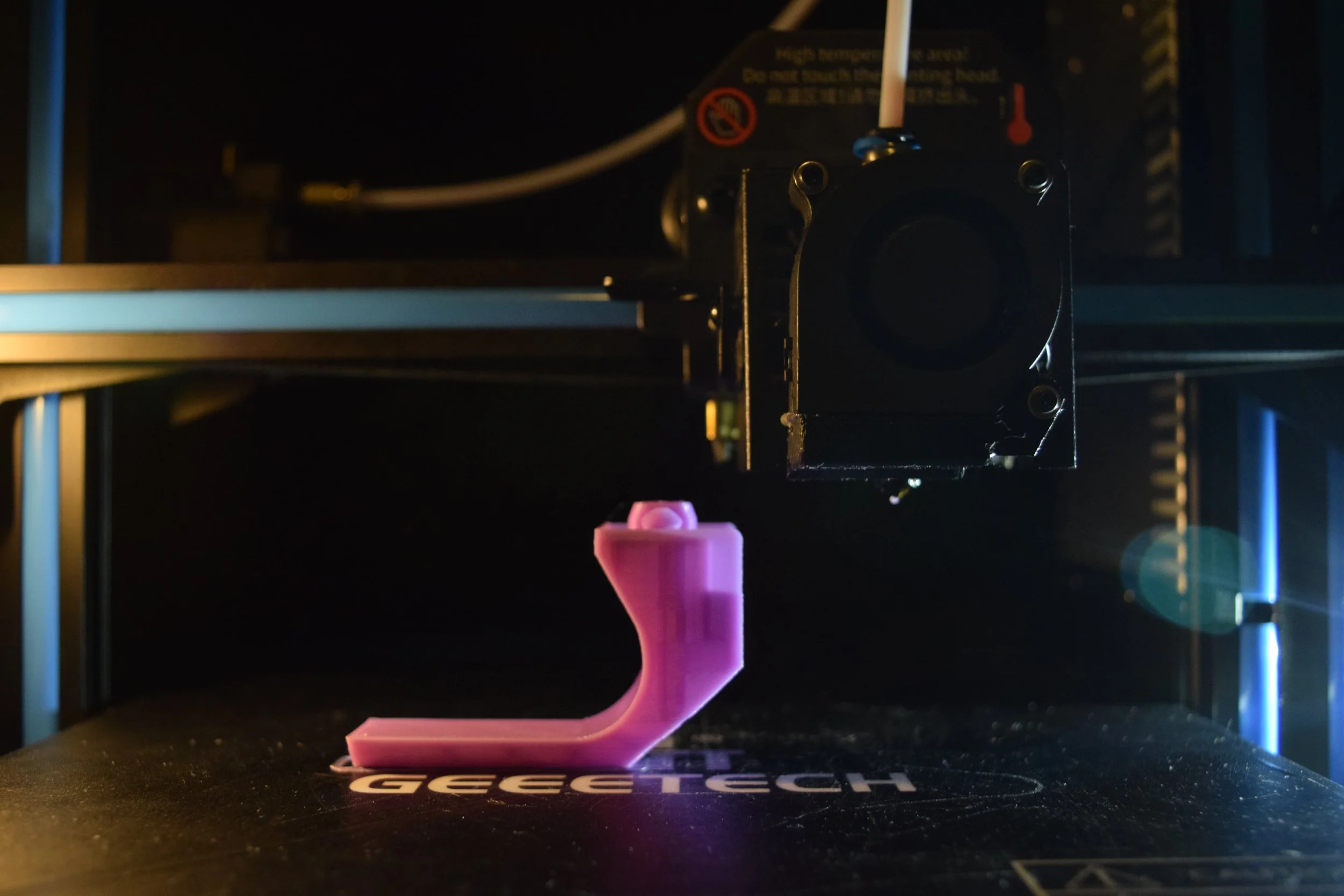

Can printers fabricate and interface with customized tools?

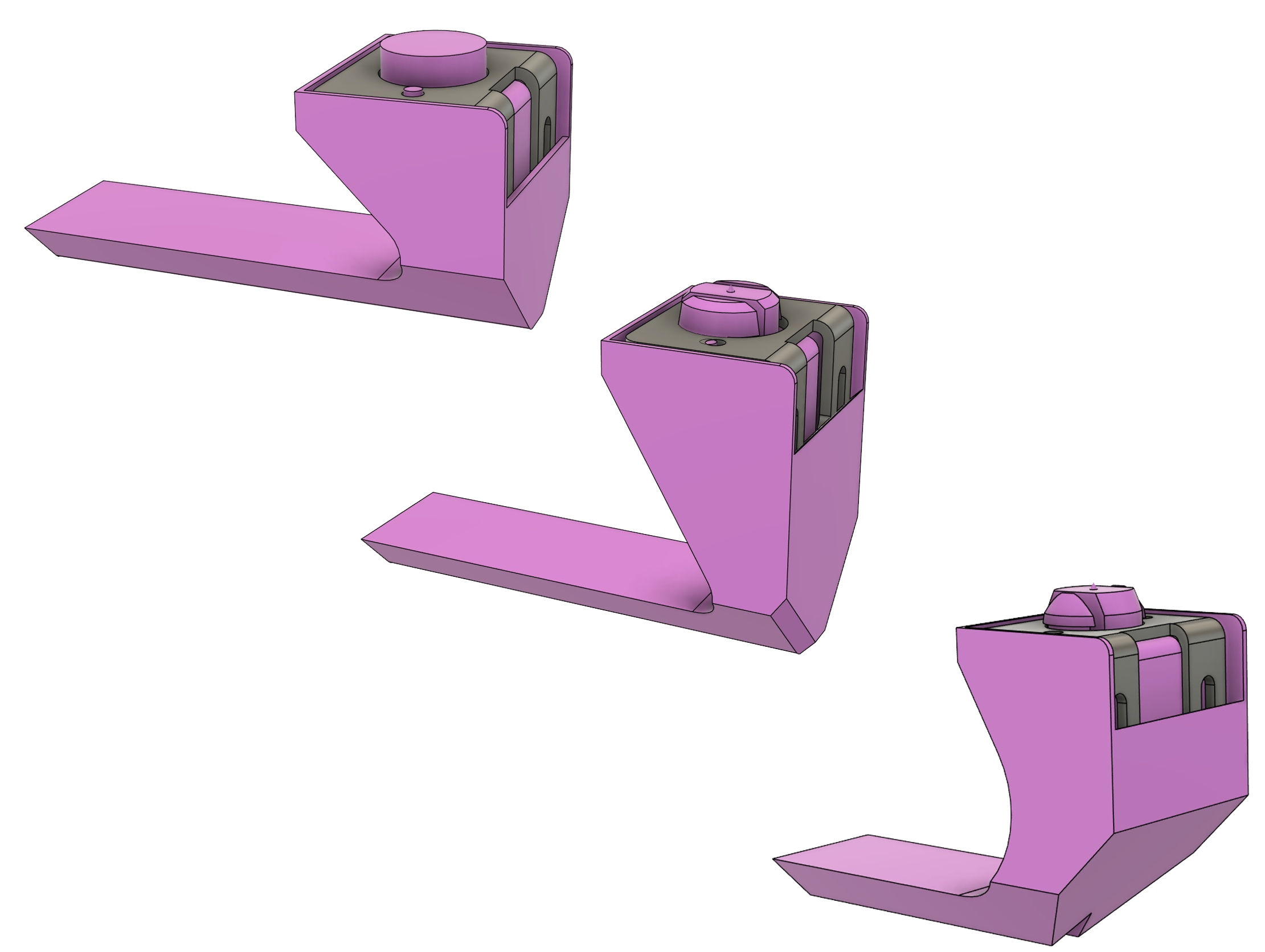

The carriage tool underwent several design iterations to function optimally. Features include:

A snap-on head designed to dock with the BL Touch Sensor bracket of an Ender 3

A sloped side profile to induce fracture propagation when lifting the tool off the build plate

A serrated bottom surface to reduce first layer surface area and improve build plate separation.

Custom g-code scripts were programmed to perform docking and support removal operations. Tool docking and separation speed was tuned to balance build plate separation with accuracy. Support clearing sweeps were coded based on part geometry, with the goal of automating the process in future work.

This project explored the potential for cheap FDM printers to print, dock, and manipulate customized tools for operations such as support clearance and part removal. The work encompassed multi-iteration CAD development of a carriage tool for support removal, custom support generation, g-code programming.

The project was summarized and published in a video format, which was shot and edited independently.

Course

MecE 408: Manufacturing Systems and Engineering

Year

August 2021

To facilitate support clearance, various custom support generation options were explored. Testing revealed that sparse tree supports with minimized post diameters were capable of holding up overhangs while remaining easy to break off from the part.